See how Texas Instruments was able to meet its own and the Department of Defense’s goals with flexibility of platforms, GUIs and easy maintenance.

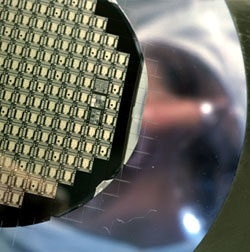

In the late 1980s, the United States Department of Defense wanted to ensure that American manufacturers could produce the micro-electronics vital to U.S. defense. To do so, the Pentagon wanted companies to develop and commercialize new technologies that would dramatically reduce the time and cost involved in producing silicon wafers and micro-electronics.

In the late 1980s, the United States Department of Defense wanted to ensure that American manufacturers could produce the micro-electronics vital to U.S. defense. To do so, the Pentagon wanted companies to develop and commercialize new technologies that would dramatically reduce the time and cost involved in producing silicon wafers and micro-electronics.

Texas Instruments (TI) took up the challenge and set a lofty goal for itself. TI wanted to cut the cost of building wafer fabrications from several hundred million dollars to $30 million and slash the production time by 90%. They also would make their process commercially available to other U.S. manufacturers.

To meet its goal, TI needed to find software that would allow them to develop a Computer Integrated Manufacturing (CIM) system, called WORKS, to oversee the process that could help them improve productivity and application quality, lower maintenance costs and take advantage of object reusability. The found their answer in Cincom VisualWorks.

VisualWorks enabled TI to develop and implement the first fully integrated prototype of the CIM system in six months, allowing them to meet the goals laid out for them by the Department of Defense.

When it came time to begin production of the lower-cost fabs, TI developers once again chose Cincom Smalltalk™ VisualWorks for its object-oriented nature and its ability to reuse code developed during the prototype phase. TI developers discovered they could use as much as 80 percent of the code they developed without modification and 10 percent with minimal changes.

This time, TI’s requirements were to support client-server computing across a wide range of platforms, a customizable Graphical User Interface (GUI) builder and support for quickly incorporating new features and functionality — all of which Cincom Smalltalk VisualWorks met.

By using VisualWorks, TI was able to not only meet its own and the Department of Defense’s goals, they were also able to offer customers flexibility in terms of platforms, GUIs and easy maintenance. TI has been able to respond quickly to customer-requested changes and incorporate new features that make the CIM application as flexible as the manufacturing process it enables.

- Click here to read the full story about Texas Instruments.

- Click here to learn more about Cincom VisualWorks.